Fuel analysis

Fuel analysis

Fuel analysis reveals more than just microbes

Read more about diesel types here.

Modern diesel engines are highly sensitive to contamination. The combination of less stable diesel and more sensitive engines has led to increased problems for diesel systems. Regular analyses detect issues before damage occurs, helping to avoid costly downtime.

We collect diesel samples and analyze the fuel in accordance with applicable standards.

We divide sampling into three categories

A: Sampling of all types of diesel in stationary tanks for pump stations, backup power, and combustion diesel:

These tests are carried out by opening the tank and taking a bottom sample. We can also take a mid-level sample of the tank’s contents, and if the fuel from the first two samples appears contaminated, a top sample may be taken as well. However, the result from the bottom test is considered the valid one.

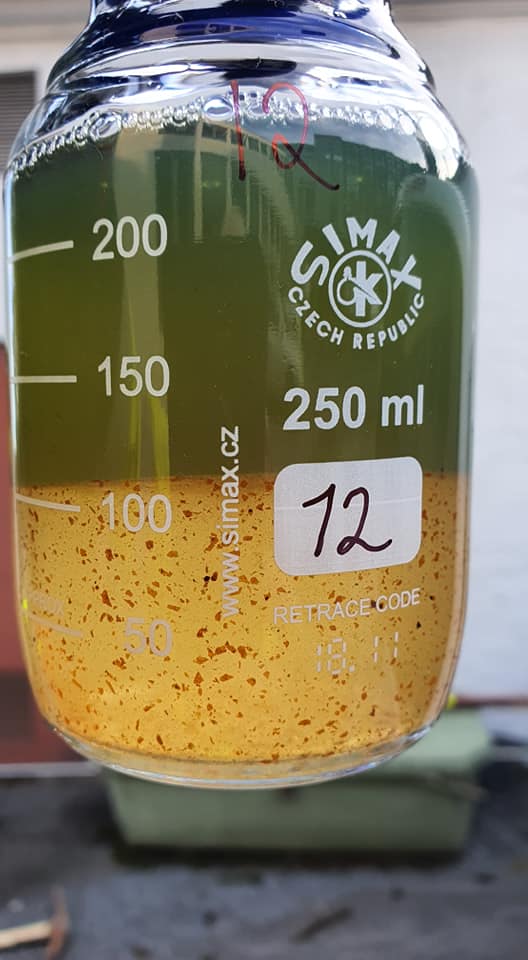

The test is taken using a special diesel sampler that is lowered into the tank and opens automatically at the specified points. The sample is then transferred to a sterile glass container in situ and labeled. If desired, each sample can be sealed, and the laboratory photographs the seal before opening and analyzing the sample.

After analysis, the laboratory provides a report revealing any contamination.

B: Sampling of diesel for construction equipment, forestry, and agricultural machinery:

These samples are taken through fuel gauges or filler pipes and transferred to a sterile glass container on site using a vacuum pump. We first carry out a visual inspection, after which the sample is sent to the laboratory for further analysis. If desired, each sample can be sealed, and the laboratory photographs the seal before opening and analyzing the sample.

C: Sampling of diesel on ocean-going vessels

These tests are carried out by drawing a measured amount of diesel from the vessel into a test tube and performing a visual inspection before sending the sample to the laboratory for further analysis. If desired, each sample can be sealed, and the laboratory photographs the seal before opening and analyzing the sample.

ISO 3170 – our professional standard for fuel sampling

All sampling is carried out in accordance with ISO 3170, the international standard for sampling of liquid petroleum products. This standard specifies how samples should be taken to ensure they are representative of the entire tank contents. The methods cover everything from the selection of the sampling point to handling, labeling, and documentation.

By following ISO 3170, we consistently obtain samples with high accuracy and traceability. Each sample is handled according to strict procedures, ensuring it can serve as a reliable basis for both technical and legal decisions. Fuel-Service carries out all sampling with precision and structure, in line with recognized international practice.

From Analysis to Action

If the fuel analysis reveals contamination, microbial growth, condensation, or particle levels outside the norm, it’s essential to take action. Untreated contamination can lead to downtime, clogged filters, injector failures, and severe engine damage. To protect equipment and extend the lifespan of tank systems and machinery, we offer a wide range of professional services.

We provide support both for preventive maintenance and in emergency situations, with personnel certified to work in confined spaces, explosive zones, and petrochemical environments.

For contaminated fuel, we offer the following services

• Diesel Cleaning

We offer the most efficient diesel cleaning on the market, designed to clean the tank while it remains in operation — with no need for draining.

• Tank Inspection with Condition Report

Visual inspection and documented assessment of the tank’s internal condition, including any recommendations.

• Ultrasonic Thickness Measurement

Inspection of tank wall thickness to detect corrosion or material loss over time.

• High-Pressure Cleaning

Efficient cleaning of tanks and piping systems with hot or cold water at pressures from 200 to 800 bar. Steam and chemical cleaning are available when needed.

• Drying After Cleaning

Removal of residual moisture to prevent condensation and new microbial growth after washing.

• Emptying and Cleaning of Dry Bulk Tanks

Complete cleaning and sanitation of storage tanks for non-liquid materials.

• Removal of Wash Water and Waste

We handle the transport and provide documented disposal of oily water and sludge in compliance with regulations.

• Flushing of Piping Systems

Flushing with crawler nozzles to remove deposits inside pipes. Can be combined with camera inspection if needed.

• Tank Disposal

We handle the removal and environmentally safe decommissioning of old or defective tanks.

• Underground Oil Tanks

Excavation, emptying, cleaning, and disposal in accordance with local and national regulations. Full documentation is provided.

• Indoor Boilers or Basement Oil Tanks

Dismantling, cleaning, and safe transport out of basements or confined spaces.

• Leak integrity testing

Control measurements and documented condition assessments of tanks and piping systems.

Modern Fuel — More Vulnerable Than Before

Today’s fuels are not what they used to be. As emission regulations have tightened and environmental considerations have increased, the composition of fuels has undergone significant changes. The result is a more environmentally friendly — but also more vulnerable fuel.

This is especially true for diesel, which previously contained high levels of sulfur and was naturally resistant to biological growth. Modern diesel, such as low-sulfur and biodiesel-based fuel (like FAME), lacks these preservative properties. At the same time, diesel is increasingly vulnerable to moisture, oxidation, wax precipitation, and microbial growth — especially when stored over time.

In addition, the use of ethanol-based gasoline (E10 and similar) can lead to water phase separation and the formation of acids, which in turn can damage both storage tanks and engine components.

Common challenges with stored fuel:

-

Quality degradation – Fuel can oxidize over time, reducing its ignition quality.

-

Water ingress – Condensation in tanks creates a breeding ground for microbes and corrosion.

-

Microbial contamination – Bacteria, fungi, and yeast can form biofilm and clog filters and injectors.

-

Rust and deposits – Reactions between moisture, oxygen, and metal tanks create rust and particles.

-

Fuel delivered below specification – Quality can vary even from professional suppliers.

-

Tank lining flaking – Old paint layers or coatings on tank walls can loosen and cause contamination.

-

Wax precipitation – In cold temperatures, paraffin wax can crystallize and clog the fuel filter.

-

Ethanol-related separation – In gasoline, water absorption can cause the alcohol to separate, reducing engine performance and increasing wear.

Regular fuel analysis is the most effective way to detect problems before they develop into downtime or costly repairs. With simple sampling, you can gain insight into the condition of the tank, the fuel quality, and any measures that may be required.

Contact us today to order a fuel analysis or for guidance on proper sampling.

Questions and answers

If the diesel does not meet the minimum requirements of EN590, it is considered contaminated and therefore condemned.

If the diesel is outside the engine manufacturer’s specifications, it may lead to engine failure — and such damage is not covered by the engine warranty.

It depends on several factors: the condition of the tank, the quality of the delivered diesel, the type of fuel, and the consumption level. For critical backup power systems (such as hospitals, data centers, and power plants), we often take samples every six months.

The shelf life of diesel varies depending on several factors. Manufacturers typically recommend a storage period of 6–12 months.